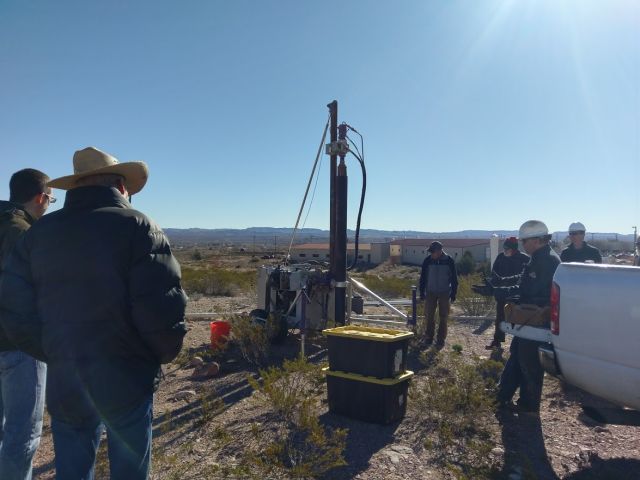

Transportable Array demonstrates its new drilling rig and sensor emplacement routine for EPIC.

March 7th, 2017

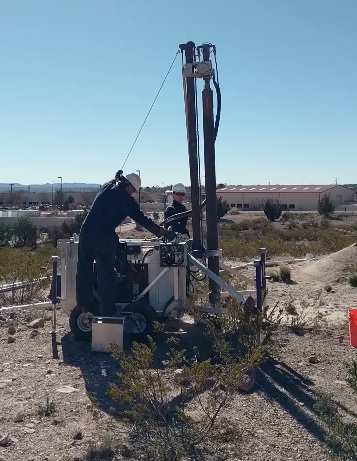

With the expansion of TA Alaska into even more remote regions of Alaska and Canada it was necessary to develop and construct an extremely lightweight, high performance helicopter portable air rotary drill weighing less than 1700 lbs and capable of installing a 6” steel casing 2.7m deep in any type of ground including solid rock, frost shattered overburden, cobbles and frozen soils. Based on these parameters, a custom drill rig system was commissioned and tested by EarthScope for specific use on the project. At EPIC we had the opportunity to be among the first testing locations for the newly constructed third generation Purple Drill. Ryan Bierma, and Max Enders along with Bob Busby from EarthScope and Mike Lundgren from Lundgren Systems (rig developer) operated the rig, and then Ryan and Max demonstrated a mock installation of an STS-5A seismic sensor at the test site behind EPIC in Socorro, NM.

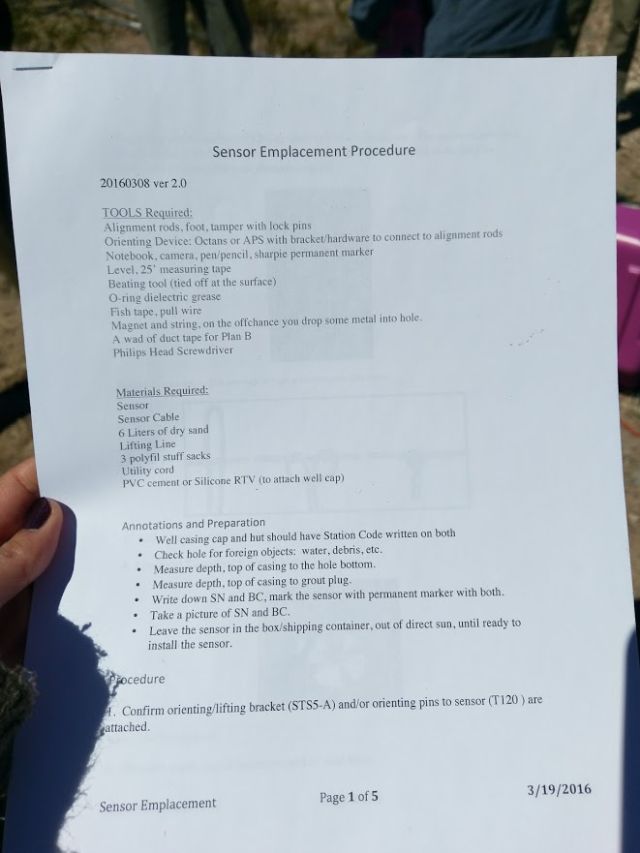

The borehole was drilled to a depth of 2.5 m while emplacing a schedule 10 steel casing at the same time. An aluminum plug was installed at the bottom of the casing, and grout was pumped into the bottom of the shallow borehole through the plug. About 2 liters of sand were poured in to the hole and tamped down to create a level surface. The sensor was then lowered to the sand layer and oriented using an OCTANS system.

- Home

- General Information

- Instrumentation

- Dataloggers

- Sensors

- All-In-One Systems

- Power Systems

- Field Procedures

- Controlled Sources

- Seismic Source Facility

- Magnetotelluric Systems at EPIC

- Ground Penetrating Radar

- GNSS/GPS Receivers

- Power and Memory Calculations Form

- Data Archiving

- Apply for a PI Account

- Experiment Scheduling

- Polar

- Hardware & Software Notes

- Software